FoodCube Origins

FoodCube, a greenhouse essential!

Featured collection

-

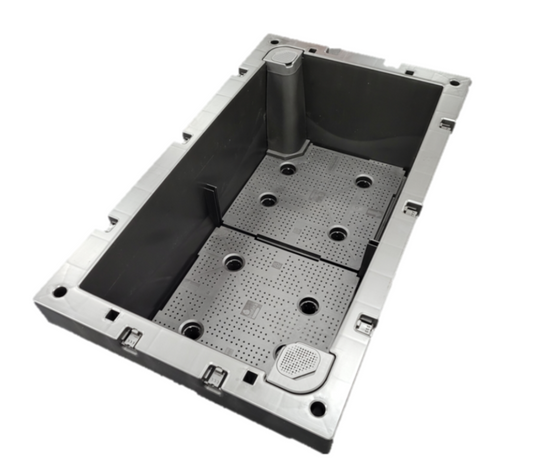

Biofilta FoodCube

Regular price $435.00 AUDRegular priceUnit price per -

Biofilta FoodCube - Premium Net System

Regular price $380.00 AUDRegular priceUnit price per -

Biofilta FoodCube - Slim Premium Net System

Regular price $285.00 AUDRegular priceUnit price per -

Biofilta FoodCube - Slim

Regular price $285.00 AUDRegular priceUnit price per